Material expertise

Steel is a fascinating material – robust yet at the same time formable.

In close cooperation with leading steelworks, Jansen Steel Tubes continously enhances its knowledge of steel, processing and the related applications. The steel grades are jointly developed with its partners in order to apply the ideal material for the respective tube application.In addition to the standard C steels, this particularly applies to the high-tensile steel grades, regardless of whether they are air-hardened materials or water-hardened manganese boron materials. On this basis, high quality steel tubes are manufactured, which ensure the application’s best processing and highest benefits.Our company’s unique material expertise in both plastic and steel represents know-how for the future and positions Jansen Steel Tubes as the perfect technology partner.

We are happy to present our competence and procedure in this area using an example. Let yourself be inspired and contact us - write your success story with Jansen Steel Tubes.

Success Story: Material expertise

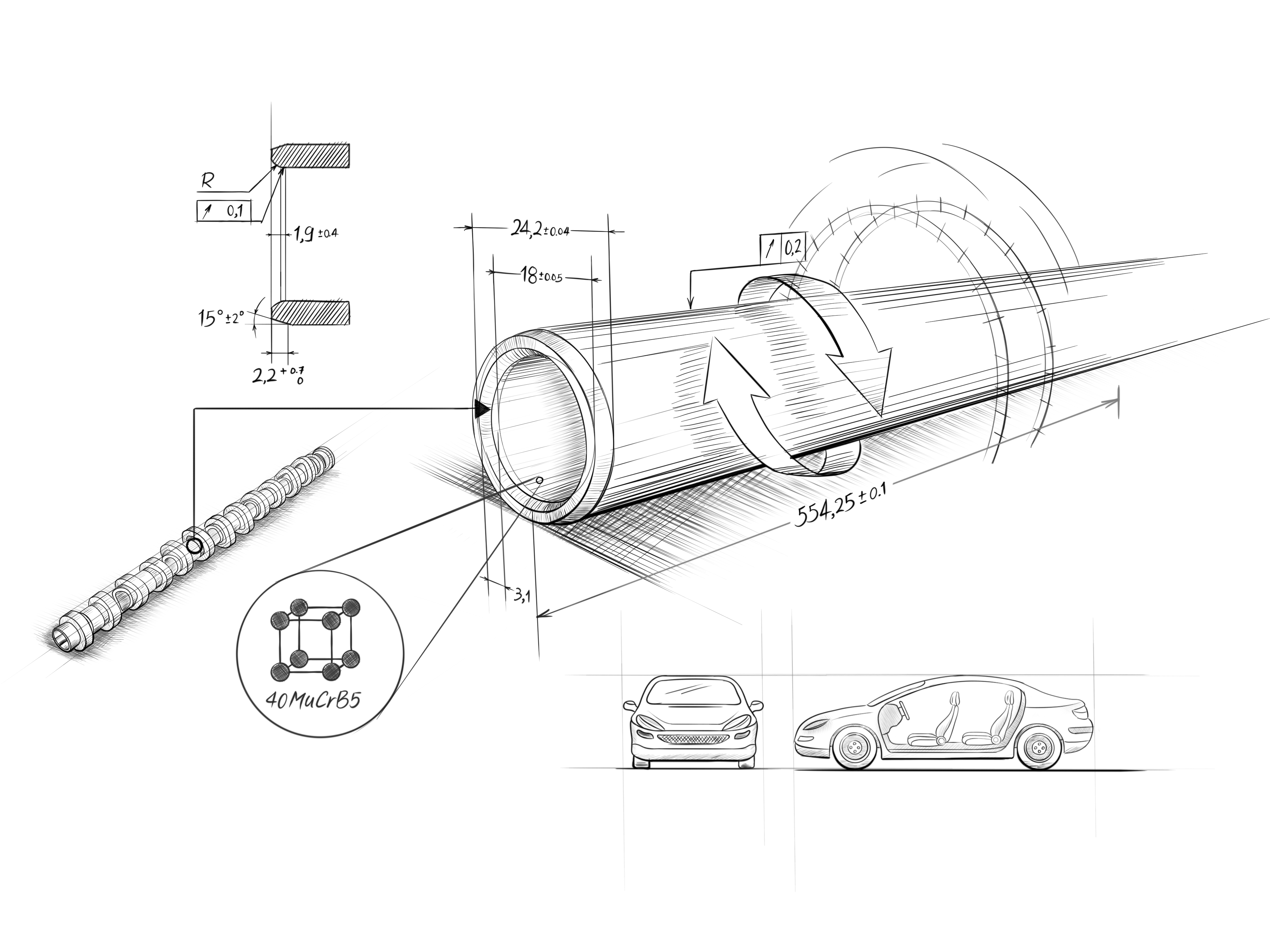

Successful use of the high-strength quality material 40MnCrB5 in series delivery

A long-term customer came to us with a special challenge for a tube section of a carrier tube, which was used as part of a camshaft with cylinder shutdown: In addition to high demands on the mass precision, the customer expected a tube with high strength and hardness and high wall thickness including one-sided wall reduction .

In cooperation with our pre-material suppliers, we were able to develop a high-strength quality 40MnCrB5 material for this application to fulfill the high strength and hardness requirements.

Thanks to the good cooperation, the mechanical properties desired by the customer could be developed and the geometric requirements for series production were implemented.

Your requirements are our incentive: We would be happy to develop an individual solution together with you.