Lightweight construction

The automotive industry is in transition. The required reduction in CO2 emissions to improve air quality and to protect the environment leads to new demands in terms of lightweight automotive engineering.

Lightweight construction, as a synonym for weight or mass reduction in vehicles, represents one of the greatest challenges for automotive manufacturers and suppliers.

Jansen Steel Tubes provides new possibilities incorporating high-tensile materials. The use of air hardening steel materials or materials suitable for tempering allows components to be lighter while maintaining their physical properties. Optimised engineering increases the production efficiency of tubes and cuts overall production costs (total cost reduction).

We are happy to present our competence and procedure in this area using an example. Let yourself be inspired and contact us - write your success story with Jansen Steel Tubes.

Success Story: Lightweight construction

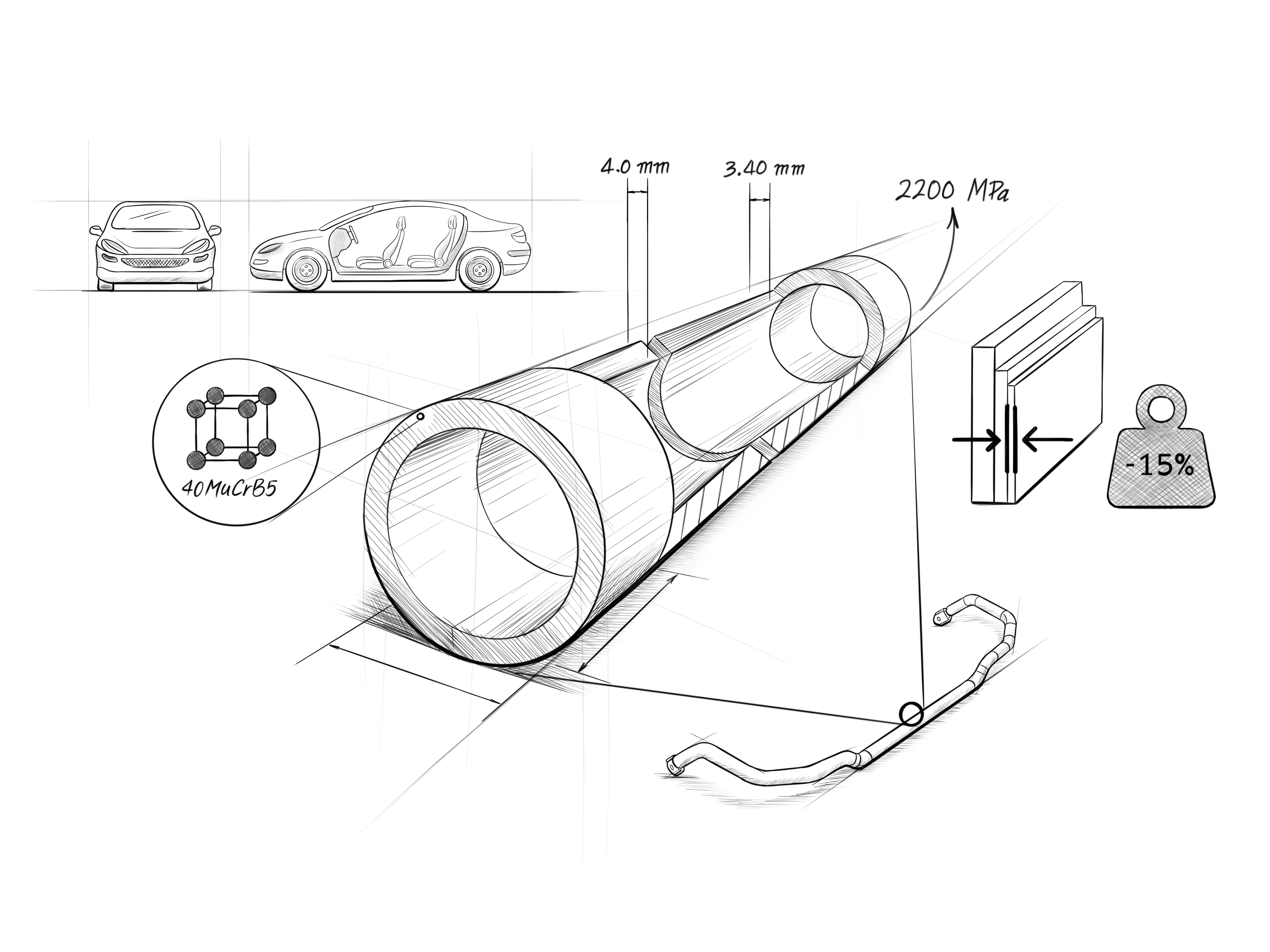

Successful weight saving of 15 percent at the stabilizer application

Due to the required weight reduction in the automotive construction to reduce the CO² emissions, a long-term customer was looking for an opportunity to make the stabilized stabilizer lighter while the physical properties should be maintained.

After a joint analysis, the use of the higher-quality material 40MnCrB5 could be designed for the strength of the stabilizer at approx. 2000 - 2200 MPa. This made it possible to reduce the wall thickness from 4.00 mm to 3.40 mm and thus also reduce the weight of the tube by 15%.

We are happy to present our competence and procedure in this area using an example. Let yourself be inspired and contact us - write your success story with Jansen Steel Tubes.